qmtprojector-100

High precision and compact equipment

High precision and compact equipment

The qmtprojector-100 is a control device accessible to all and intended particularly for production control in the microtechnology and watchmaking sector. It allows high-precision measurement of the dimensional characteristics of static parts in the open field.

Quick and easy to use, the part is simply placed to measure it reliably and precisely. With a robust design and equipped with an integrated computer, it benefits from the qmtmesure-pro software. which offers business applications without programming.

With the qmtvline , it measures turned parts without adjustment and straightening. The measurement is therefore very fast and precise. Custom functions can be developed under the qmtf4u customization program.

- Versatility: flat parts without laying, turned parts with the qmtvline , beats with the qmtwheeltest-vision technology

- High precision: qmtjust to guarantee metrological performance

- Great ease of use even for complex measurements

- No alignment: reliable and very fast measurement of turned parts with the qmtvline fixture

- qmtsixsigma option for APC (Automated Process Control)

Available for rental

- Delivery within 4 weeks

- Commissioning and training by qmt

- Flexible rental period per monthly period (no commitment)

- Preventive maintenance and calibration are performed by qmt annually

- Possibility of acquiring the equipment after rental

Customizable solutions to perfectly meet your needs

Measurement of turned parts

SIMODEC Innovation Trophy for the qmtprojector-100

Beat measurement

Board measurement

Measuring threads

Patented installation qmtvline

A full-field optical inspection device

qmtprojector-100 technologies

The qmtprojector-100 is a device developed by qmt to meet the specific needs of measurements in the microtechnical fields and in particular watchmaking.

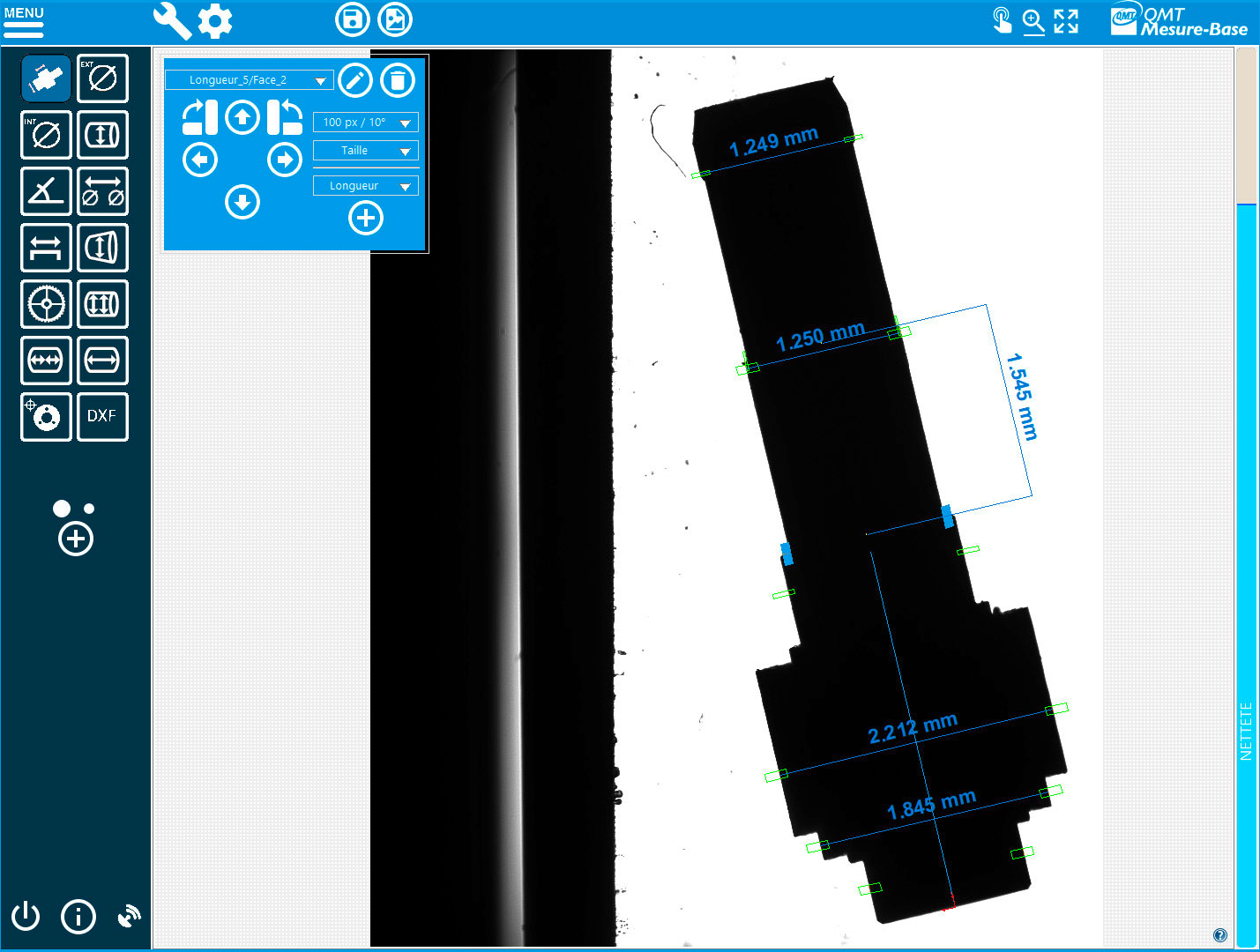

The qmtprojector-100 has an optical system that acquires the image of the entire field of view at very high resolution and in one image capture. The image of the part is therefore visible and constantly refreshed, at the same time all the measurements are taken and displayed.

The qmtprojector-100 has small dimensions (560 x 210 x 350mm) and is fully integrated including the computer system. Just plug the qmtprojector-100 into electricity to use it.

With the telecentric lens, the very high resolution camera and the qmtjust calibration

The control program is carried out using a simple interface with standard sequences

For the measurement, without programming, of complex parts such as boards, anchors, screws, ...

For simple, fast and high-precision measurement without adjustment or alignment

Compact, integrated and precise

| Functions | Field 8.5 x 7.1 | Field 16.0 x 13.4 | Field 28.5 x 23.6 |

|---|---|---|---|

| Accuracy [μm] | 0.7 | 1.4 | 2.3 |

| Qmtvline installation | Optional installation with tools and software functions (BQ009AA003) Maximum workpiece size of 7.5x5mm | ||

| Lighting | Telecentric Diascopic | ||

| Measurement software | qmtmesure-pro | ||

| qmtcalquecontrol (DXF) | Overlay with automatic positioning | ||

| Advanced metrological functions | Planks, screws, taps, turned parts, ... Complete list available under optional functions table | ||

| qmtsxisigma | Qmtf4u customization | ||

| Computer science | Integrated into the equipment with 23 "touch screen | ||

| Focus (z axis) | Manual | ||

| Dimensions (H x W x D) [mm] | 560 x 210 x 350 | ||

| Item codes | AQ009AA001 | AQ009AA002 | AQ009AA003 |

All solutions are based on unique software functions

For optical control

To increase production yields

and the quality of the parts

For aesthetic control

For acoustic and vibration control

Dimensional control with the QMTProjector

QMTProjector devices are easy to use and efficient

reading