QMT expertise

for automated quality control solutions to guarantee zero defects

QMT introduced the concept of Mechatronic Inspection

Most current measurement systems add no value to the inspected product. Based on this observation, qmt introduced the concept of Mecatronic Multiple Inspection Systems™ to push the boundaries of measurement by combining multi-signal inspection with all types of operations.

QMT's expertise in implementing solutions

Understanding the client's needs, defining the optimal solution architecture, and integrating the system into the client's environment.

Software development or customizations integrating signal acquisition, processing, communication, and results management

Design and development of Multi-Inspection Mechatronic (M2IS) systems for testing and micromanipulating devices to be controlled

Development and design of innovative optical systems and algorithms to reproduce human vision (3D vision, augmented stereoscopic vision, etc.)

Integration of multi-physics measurements (torque, force, velocity, position, etc.) into systems to enable characterization and automation

Model selection, dataset creation, data management, and integration into an automated process

We contribute to our clients' development for lasting prosperity

Through vision, through hearing, through automated solutions integrating artificial intelligence, qmt limits the number of imperfections in what will or can be manufactured.

About qmtA team deployed across our two sites in Geneva and Chambéry

With our extensive know-how, we build a reliable partnership with our clients to develop solutions and support their success by improving quality and efficiency.

The qmt teamWe will never achieve perfection, but we work towards it every day.

qmt developed the Multimicro in 1991 (motorized image analyzer with automatic microhardness measurement), which was awarded a Credit Suisse prize. In 2015, qmt won the Geneva Canton Innovation Prize.

Historical

Measurement and quality control based on multiple signals

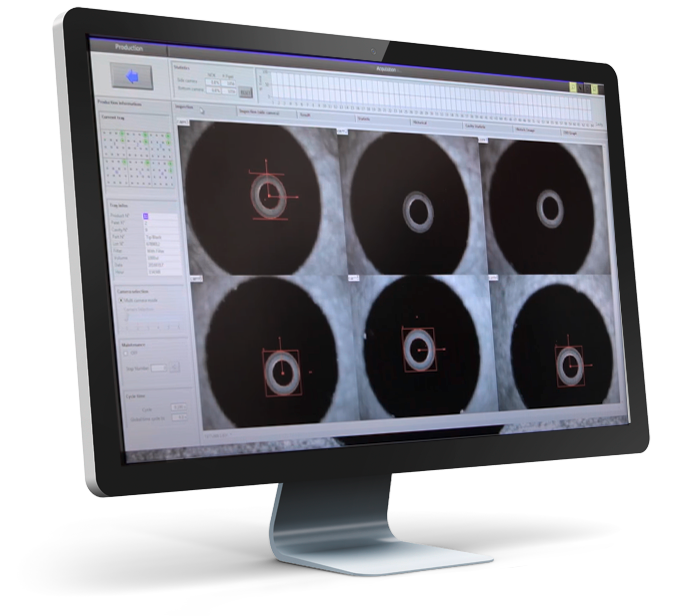

qmt offers automated quality control solutions with multi-signal inspection. Each system can integrate a single type of signal or combine several signals, in particular optics and acoustics.

- Traditional vision by camera but also new optical technologies

- Acoustics and vibration

- Physical characteristics and electrical signals

Example of automated quality control