Quality control of medical pipettes

Very high speed dimensional and aspect checks

The quality control and sorting system for medical pipettes

Pipettes are used in the medical industry to perform small volume assays. To guarantee the precision of this dosage, the pipette tips must have a geometry as well as a perfect surface condition.

The production process by plastic injection of pipettes does not allow total control of quality. 100% automatic control is therefore necessary

qmt has developed the qmtsort-tip measuring station for testing plastic pipettes. This checks the dimensions as well as the surface condition of the products leaving the injection machine at a rate of 20 pipettes per second.

qmtsort-tip pipette measuring station

qmt has developed and industrializes the qmtsort-tip station for 100% quality control of medical pipettes. To guarantee the precision of this dosage, the pipette tips must have a geometry as well as a perfect surface finish.

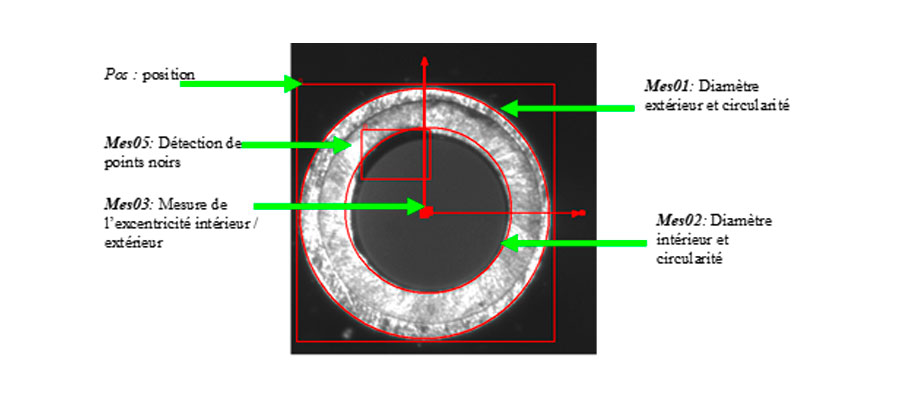

readingqmtsort-tip controls the following 7 parameters for each tip:

- Mes04: Surface homogeneity

- Mes06: Presence of injection burrs inside the tip

- Mes07: Presence of a filter

Typical pipette tip dimensions are 0.5mm inside diameter (+0.050/0 tolerances) and 0.9mm outside diameter (+0.025/-0.025 tolerances).

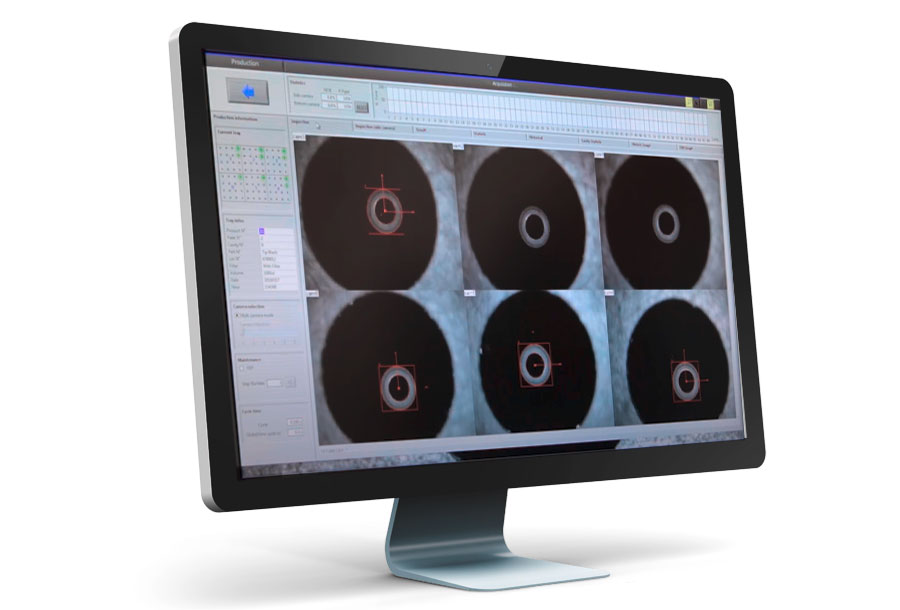

The pipettes are packaged in racks, a motorized system comprising two servomotors performs the movements in order to allow scanning. In order to guarantee an optimal cycle time, qmtsort-tip includes six optical assemblies which work in parallel and are synchronized with the movement of the two axes (see diagram below). The control of a rack of 120 probes therefore represents the acquisition and processing of 120 images involving 840 results (7 controls per probe).

The system includes standard LED diascopic illumination and 6 incidental illuminations developed specifically for this application in order to guarantee very high power and a small footprint.

The integrated computer system communicates with the entire machine through opto-isolated 24VDC digital lines and an OPC server for reference selection and traceability management.

The control and supervision software has been developed to be used by operators without specific IT skills. It is multi-language and the user interface is graphical only.

The qmtsort-tip software includes an easy-to-use control (reference) program creation mode so that customers can create custom programs. The control programs are memorized and can therefore be recalled during subsequent productions.

The qmtsort-tip software allows the saving of the results as well as the images in order to allow a follow-up of the production history as well as an understanding of the detected defects.

qmtsort-tip is a product developed together with Zubler Handling AG within the framework. It is standardized to be installed on Zubler automatic lines. qmtsort-tip is a measurement station , therefore a sub-assembly which is integrated into a complete machine. It includes hardware, software and hardware.

qmtsort-tip is a product that meets a very strong demand. It has been deployed successfully for more than 10 years with installations in Switzerland, Germany and the United States.

Manufacture of pipettes incorporating qmtsort-tip

Presentation of a Zubler pipette manufacturing machine.

qmtsort-tip is integrated into this machine

reading