qmtprotime

For the measurement of daytime steps

Range of equipment for measuring the daily rate of finished watches and movements

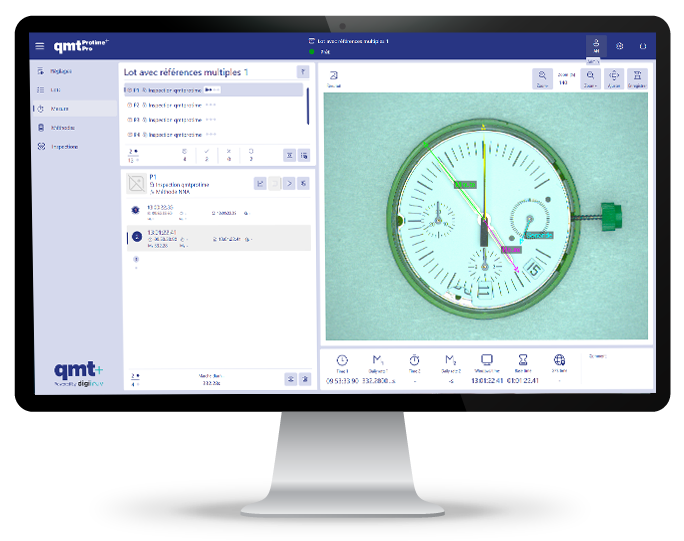

The measurement is based on taking two images of the product spaced apart in time, which are time-referenced using a precision time base. The time indicated by the watch or movement in both states is given by the position of the hands, which is defined in the high-resolution image. The rate can thus be calculated using the difference between the state difference of the watch and the time difference defined by the time base.

The time calculation algorithm takes into account discontinuous displays (e.g., hand jumps) and display desynchronizations. The laboratory mode allows high-speed, continuous measurement of the position of the indicators to enable advanced analysis of the movement's operation.

- The average measured rate corresponds perfectly to the customer's perception, on finished watches and movements of all types

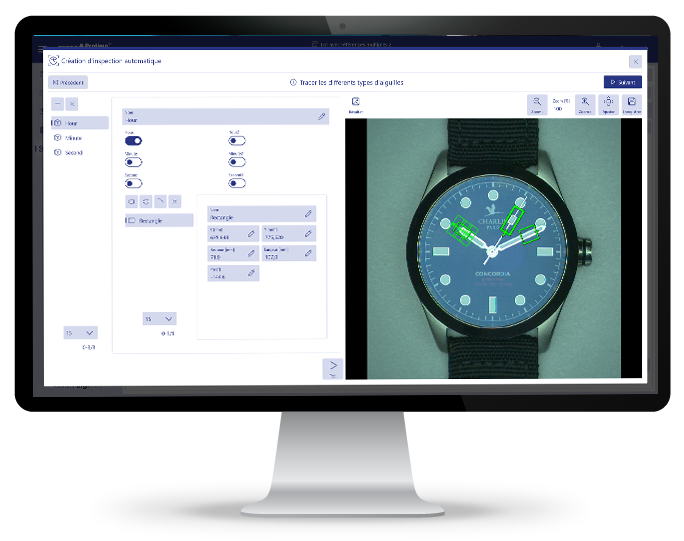

- A recipe creation without programming with integration of Artificial Intelligence and an intuitive user interface

- Robust and more accurate measurement algorithms

- Modular software that allows the creation of custom functions so that the product can easily adapt to specific customer needs, particularly for data management

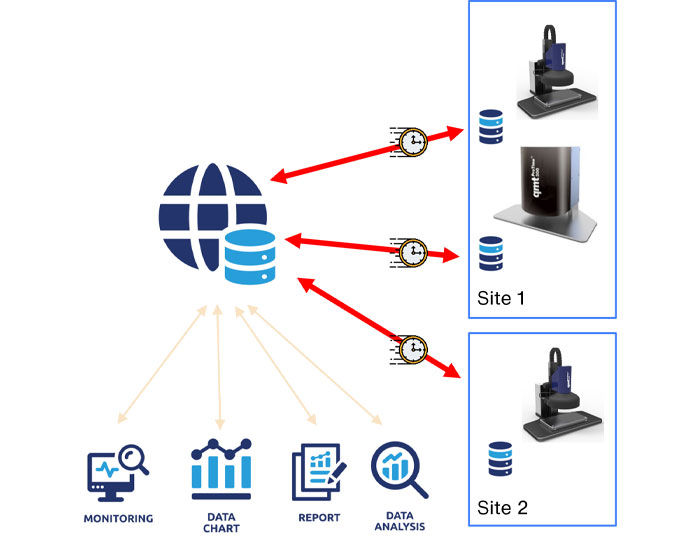

- Multi-device measurement: shared and versioned measurement programs

Customizable solutions to perfectly meet your needs

The latest generation of daytime walking measurements

Next-generation qmtprotime technologies

The new generation of qmtprotime incorporates a new needle detection algorithm to handle overlaps and crossings, while improving detection accuracy and measurement speed.

The qmtprotime's versatility meets the needs of precision control of your movements or watch heads in the laboratory and in production. It can be used on a watchmaker's bench or integrated into an automated cell.

High-resolution color camera (5Mpix) with a fast acquisition speed. The camera is electrically synchronized with the time base and lighting in order to be able to time-stamp images with guaranteed accuracy.

The qmtprotime's lighting limits reflections on watch crystals and prevents shadows. Simplified control allows for quick and easy adjustment of contrast and brightness. The lighting adapts to any crystal shape thanks to its specific geometry.

New, more robust and accurate vision tools improve time reading rates. They allow you to adapt your measurement inspections to a wide range of movements or finished watch heads.

Using a standard Windows 10 or 11 64-bit PC, a client PC can be used.

Creation of measurement inspections

Data management

Intuitiveness and customization capability

Reference time and synchronization

More than 35 years of history

A history marked by innovation. qmt developed the Multimicro in 1991, which received an award from Crédit Suisse (motorized image analyzer with automatic microhardness measurement). In 2015, qmt won the Geneva Canton Innovation Award.

Our historyDaytime walking measurement for all applications

| Functions | qmtprotime-200 | qmtprotime-300 | |

|---|---|---|---|

| Product packaging | Tray 315 x 172mm with manual movement |

Integration into automatic line | |

| Room typology | 50 x 50mm, finished watches, movements and movements in caps All types (needles, discs, off-center, etc.) |

||

| Measurement cycles | Compliance with ISO3159 (COSC), METAS N001 and Poinçon de Genève standards; personalized cycles | ||

| Measures | Manual or automatic status measurements, daytime operations, continuous status measurements (laboratory mode) | ||

| Image resolution | 5MPix | ||

| Focus type (z axis) | Manual | Motorized | |

| Time bases and precisions |

TCXO oscillator (4msec/day) GPS or NTP connection options (< 1msec/day) |

||

| Uncertainty in daytime walking measurement | +/- 0.08 sec/day 2 status reports spaced 24 hours apart |

||

| Data management | Local operation or centralized management with automatic resynchronization in the event of a network failure | ||

| Computer science | Standard or industrial PC Windows 10 or 11 (64-bit), customer supply possible | ||

| Dimensions (H x W x D) | 550 x 555 x 435mm | 500 x 340 x 300mm | |

| Item code | AQ015AA005 | AQ015AA004 | |

Available for rental

- Delivery within 4 weeks

- Commissioning and training by qmt

- Flexible rental period per monthly period (no commitment)

- Preventive maintenance and calibration are performed by qmt annually

- Possibility of acquiring the equipment after rental

All solutions are based on unique software functions

For optical control

To increase production yields

and the quality of the parts

For aesthetic control

For acoustic and vibration control